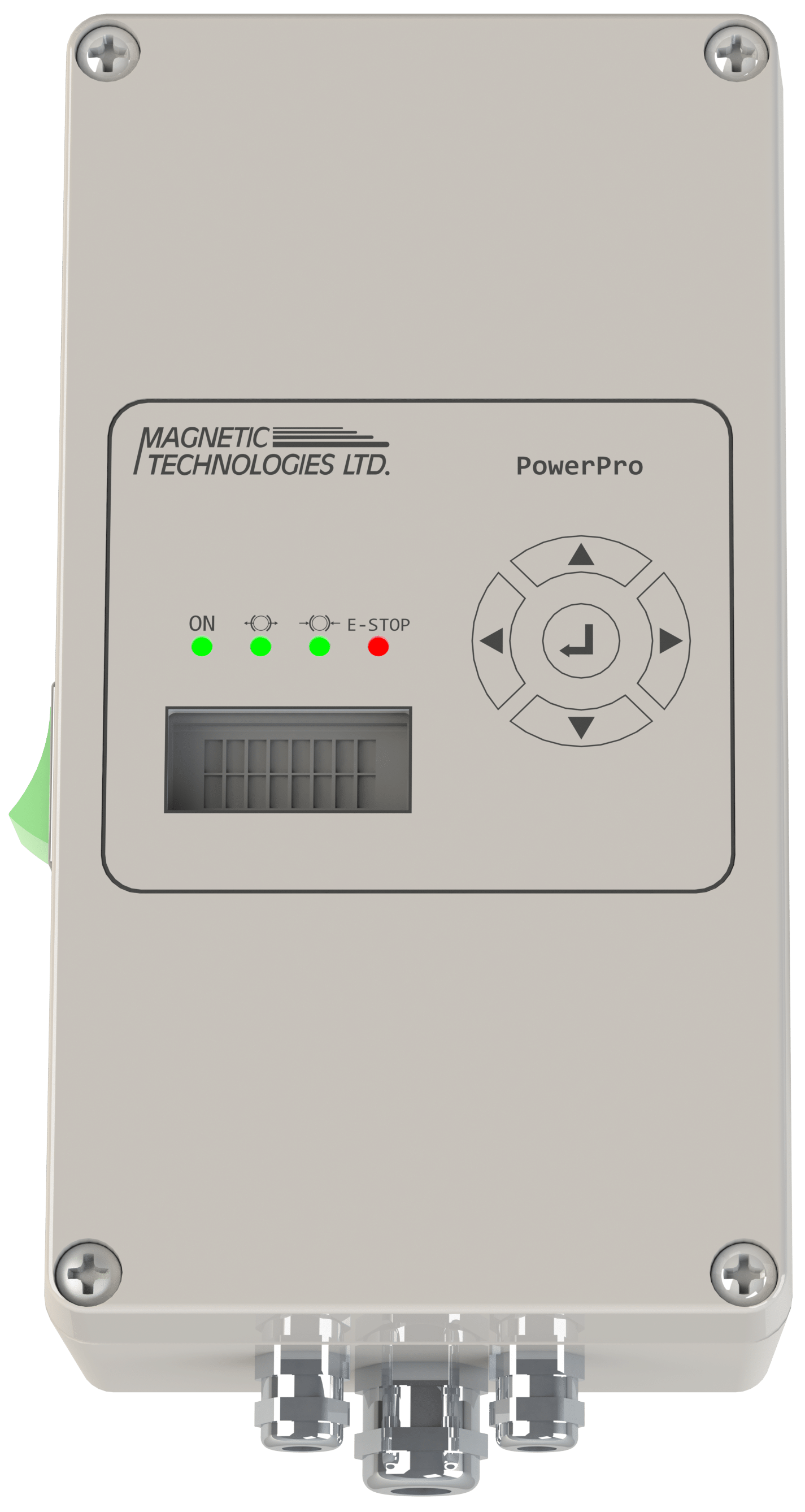

PowerPro24 for precise tension control

The Latest Innovation in Tension Control

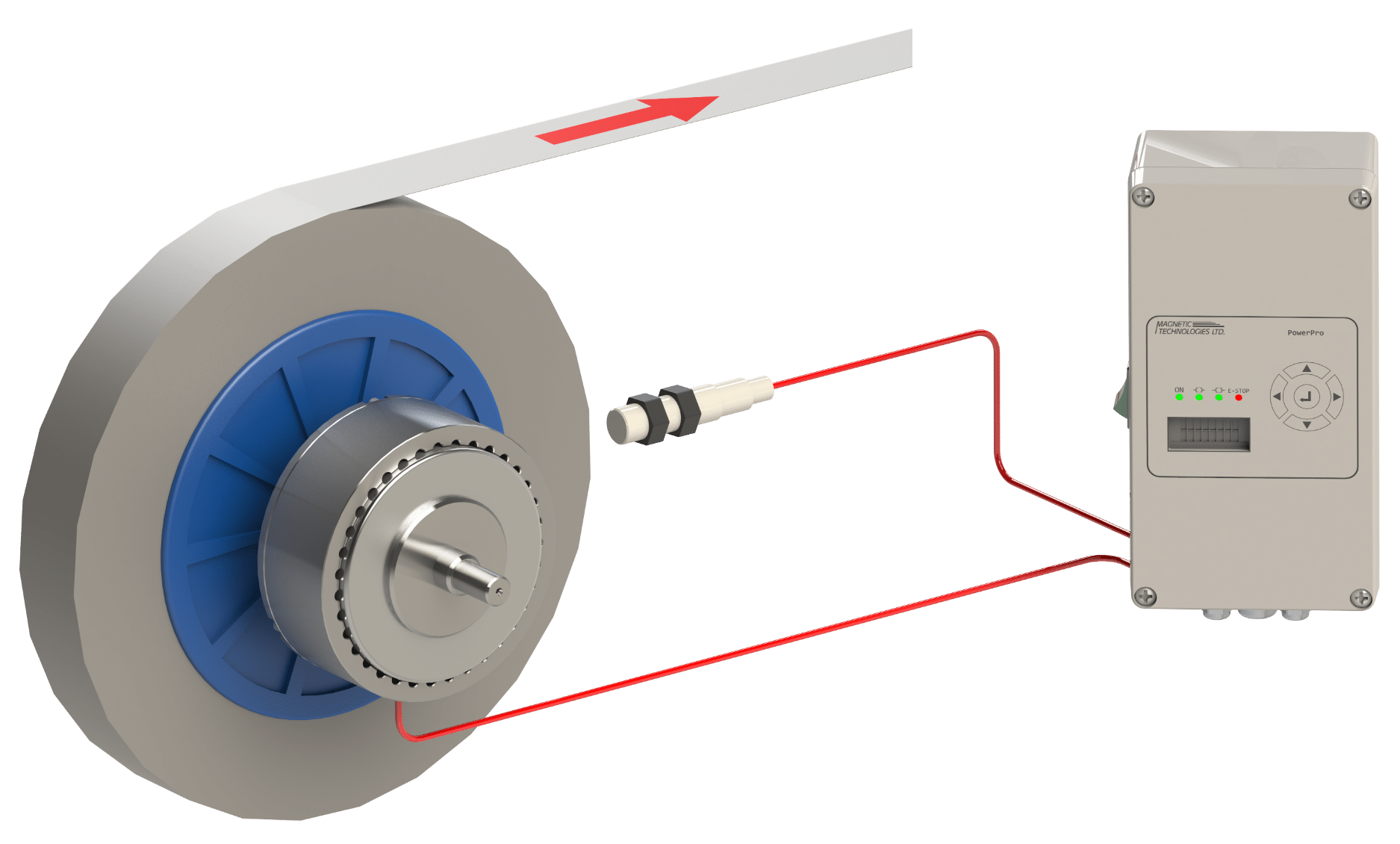

Magnetic Technologies PowerPro24 (MPP24) is a modern, microprocessor controlled constant current digital power supply and tension controller. MPP24 is specifically designed for use with our line of Electric Hysteresis Brakes.

We have been involved in the wire, cable, and tension-control industries for over 30 years, transforming it from leather and rope brakes to permanent magnet brakes for better tension control. However, in the 21st century, the need for even more precise tension control is becoming more prevalent, and maintaining constant tension in payoff applications has become a necessary prerequisite for precision manufacturing in the industry.

When we began building constant tension controlled payoffs, we found the industry offered no complete tension control solutions. The solutions that were available required numerous expensive and complicated components and days to setup, calibrate, and tune.

As we encountered more applications that required precisely controlled constant tension, we used our experience and expertise in the field to develop the first fully integrated tension controller power supply. After years of development, the MPP24 has allowed us to increase tension accuracy, decrease packaging size, and decrease system complexity, all while significantly decreasing total system cost.

Operating Modes

A Complete Solution

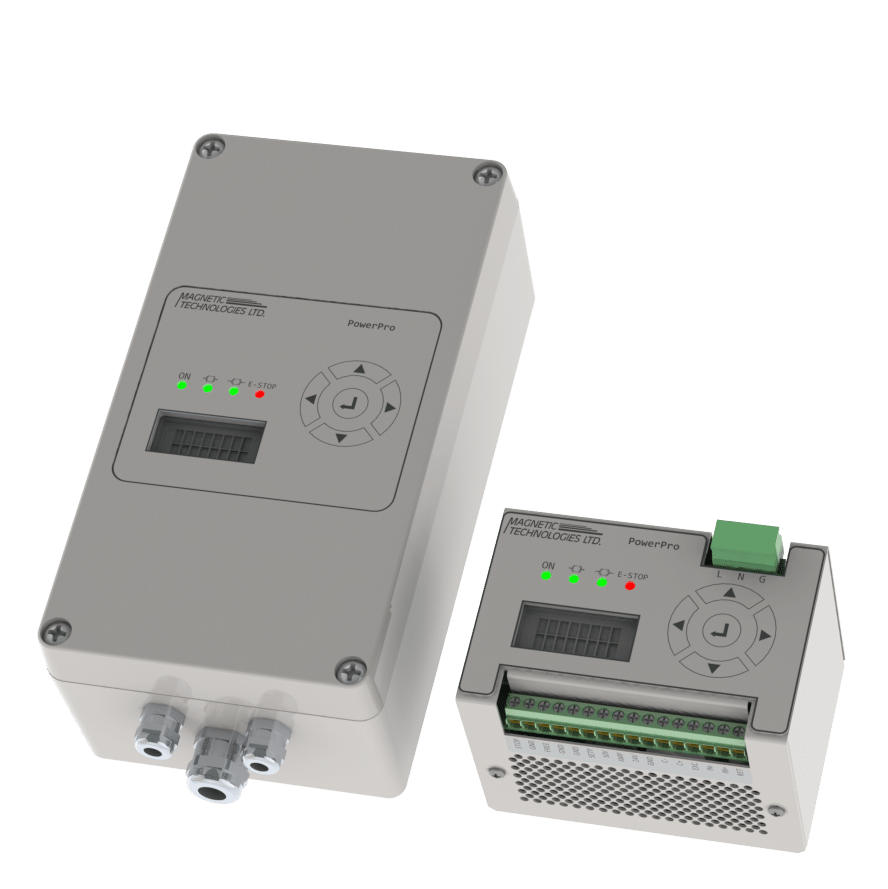

At a fraction of the cost of a traditional tension controller, the PowerPro24 fully integrates the entire system into one compact device.

Conventional System

PowerPro24

0-10VDC Input

Ultrasonic

0-10VDC Input

Ultrasonic

0-10VDC Input

Ultrasonic

Strain Gauge

0-10VDC Input

Ultrasonic

Strain Gauge