Selection Criteria

For every application determine the TORQUE and MAXIMUM RPM. Example Selection Criteria

| Metric | English | |

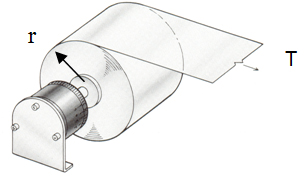

| Line Tension (T) | 8N | 1.8 lb |

| Full Spool Radius (r) | .15m | 5.9 in |

| Spool Core Diameter (d) | .125m | .41 ft |

| Line Speed | 90 m/min | 295 ft/min |

Step 1– Calculate Maximum Torque

The line tension multiplied by the radius of a

full spool.

Example:

Full Spool Radius (r) x Line tension (T)= Torque

.15m x 8N =1.2Nm or 5.9 in x 1.8 lb= 10.6 lb-in

Selection: In this example select Model EB-140 or larger.

Step 2– Calculate MAX RPM

When a magnetic brake shaft is turning, mechanical energy is converted into thermal energy (watts). The amount of thermal energy (watts) is a function of RPM and TORQUE.

| Example Max | = Line Speed______ | = 90m/min___ | =295 ft/min__ | =229 RPM |

| Calculation: | RPM 3.14x Core Dia (d) | 3.14 x .125m | 3.14 x .41 ft | |

Step 3– Calculate Power Dissipation

| Example Calculation: | P (watts) | = T(lb-in) x RPM | = 1.2 x 229 | = 29 watts |

| 9.55 | 9.55 | |||

| Example Calculation: | P (watts) | = T(lb-in) x RPM | = 10.6 x 229 | = 29 watts |

| 84.36 | 84.36 | |||

Selection: In this example P=29 watts. The Model EB-140 is rated for 75 watts continuous and 500 watts for 5 minutes.

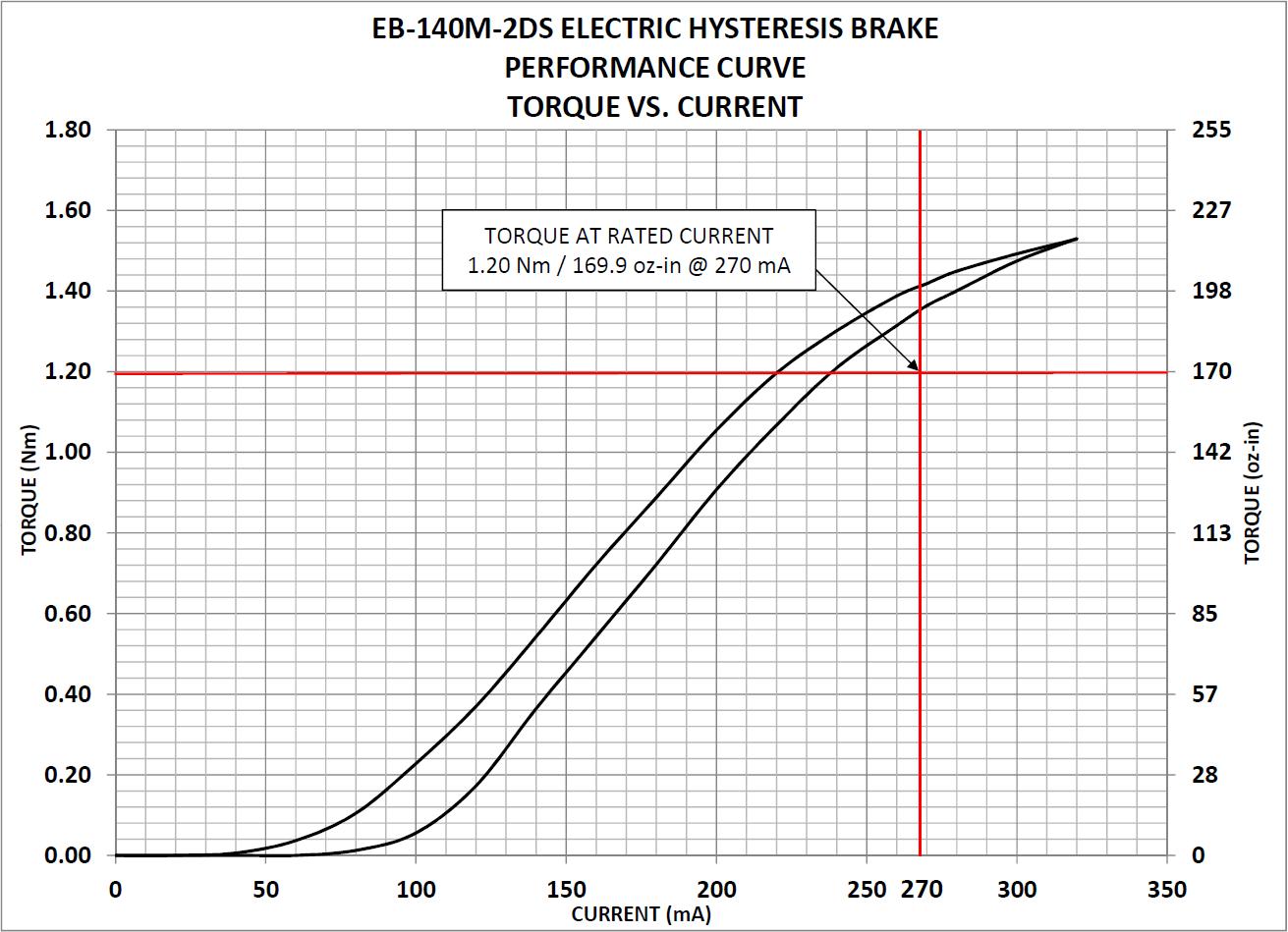

Step 4– Determine Operating Current

From the product data sheets examine the Performance Curve to determine the approximate operating current.

Solution: In this example the EB-140 Performance Curve is shown below. Our previously determined 1.2Nm, requires a maximum current of 270mA @ 24VDC. Typically the brakes have a 15-35% safety factor, so that the actual current will be 230mA (from the chart below)