Magnetic couplings offer a non-contact transfer of torque. They are typically used in pumps for seal-less applications; keeping corrosive, toxic, or flammable liquids from escaping into the atmosphere.

Magnetic couplings offer a non-contact transfer of torque. They are typically used in pumps for seal-less applications; keeping corrosive, toxic, or flammable liquids from escaping into the atmosphere.

Simple Concept: Opposite Poles Attract.

This attraction is how we transmit torque from one magnetic hub to another. By driving one magnetic hub, torque is transmitted magnetically to the other magnetic hub. This can be done through the air or through a non-magnetic containment barrier such as stainless steel or fiberglass, allowing complete isolation of the inner magnetic hub from the outer magnetic hub. There are no contacting parts.

How Co-Axial Couplings Work

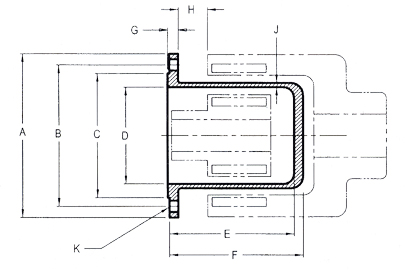

The co-axial coupling consists of three parts. The outer hub consists of a series of rare earth magnets that are ground, potted and attached to the inside diameter of a steel hub. The inner hub consists of a series of rare earth magnets that are ground, potted and attached to the outside diameter of a steel rotor. The inner hub is then completely sealed in stainless steel to protect the magnets and rotor from damage or corrosive substances. Typically there is a radial air gap of up to .275” (7mm) between the inner and outer hubs. Conventional bores and keyways are used to drive the inner and outer hubs.

Specifications – Shown in English measure

( Click here for English Measure)

Note: The dimensions and ratings for all co-axial type couplings are shown using only  NdFeB type rare earth magnets. Ratings and dimensions may vary for the SmCo versions.

NdFeB type rare earth magnets. Ratings and dimensions may vary for the SmCo versions.

Advantages of Co-Axial Type Couplings

- Eliminates Rotating Seals

- No Wearing Parts

- Synchronous Design, No Slip at Any Speed

- No Physical Contact Between Driving and Driven Parts

- Custom Designs Available

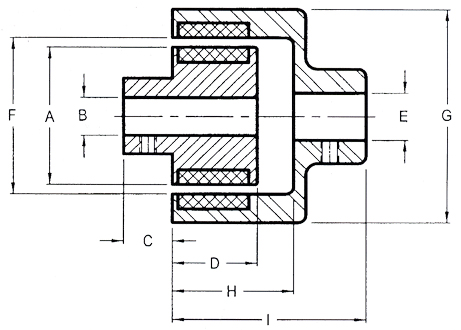

| MTC-0.1 thru MTC-10 | INNER HUB | OUTER HUB | SOLID MODEL .SLDPRT |

.STEP | ||||||||||||||

|

Part Number

|

Max

Speed (rpm) |

Total

Weight (kg) |

Nominal

Torque (Nm) |

Peak

Torque (Nm) |

A

(mm) |

B

(mm) |

C (mm) |

D (mm) |

E

(mm) |

F

(mm) |

G

(mm) |

H

(mm) |

I

(mm) |

|||||

|

MTC-0.1

|

44000 |

0.1

|

0.1

|

0.2

|

12.7

|

5

|

7

|

15

|

6

|

18

|

26

|

19

|

30

|

|||||

|

MTC-0.3

|

26000

|

0.3

|

0.3

|

0.5

|

22

|

8

|

8

|

16

|

8

|

28

|

44

|

22

|

36

|

|||||

|

MTC-1

|

22000

|

0.8

|

1.0

|

1.5

|

28

|

10

|

12

|

20

|

10

|

35

|

52

|

28

|

44

|

|||||

|

MTC-3

|

18000

|

1.0

|

3

|

3.5

|

35

|

12

|

16

|

32

|

12

|

42

|

64

|

42

|

62

|

|||||

|

MTC-10

|

13000

|

2.5

|

10

|

12

|

58

|

16

|

20

|

35

|

20

|

66

|

90

|

50

|

80

|

|||||

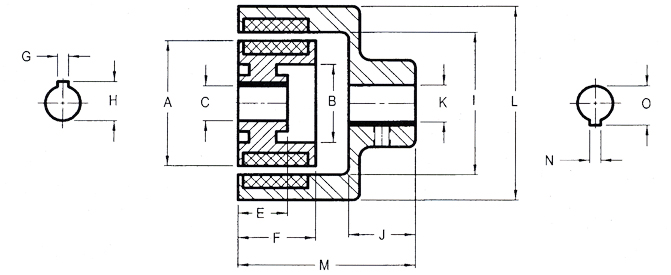

| MTC-16 thru MTC-140 | INNER HUB | OUTER HUB | ||||||||||||||||||

|

Part Number

|

Max

Speed (rpm) |

Total

Weight (kg) |

Nominal

Torque (Nm) |

Peak

Torque (Nm) |

A

(mm) |

B

(mm) |

C

(mm) |

E

(mm) |

F

(mm) |

G

(mm) |

H

(mm) |

I

(mm) |

J

(mm) |

K

(mm) |

L

(mm) |

M

(mm) |

N

(mm) |

O

(mm) |

||

|

MTC-16

|

13000 |

3.0

|

16

|

26

|

58

|

26

|

14

|

20

|

62

|

5

|

16.3

|

66

|

40

|

19

|

90

|

120

|

6

|

21.8

|

||

|

MTC-22

|

9400

|

7

|

22

|

35

|

88

|

50

|

20

|

30

|

50

|

6

|

22.8

|

97

|

50

|

24

|

124

|

120

|

8

|

27.3

|

||

|

MTC-30

|

9400

|

8

|

30

|

48

|

88

|

50

|

24

|

30

|

62

|

8

|

27.3

|

97

|

50

|

28

|

124

|

130

|

8

|

31.3

|

||

|

MTC-50

|

7300

|

12

|

50

|

80

|

122

|

80

|

30

|

30

|

50

|

8

|

33.3

|

132

|

60

|

38

|

160

|

130

|

10

|

41.3

|

||

|

MTC-65

|

7300

|

15

|

65

|

100

|

122

|

80

|

30

|

40

|

65

|

8

|

33.3

|

132

|

60

|

38

|

160

|

145

|

10

|

41.3

|

||

|

MTC-80

|

6500

|

19

|

80

|

130

|

142

|

90

|

35

|

40

|

65

|

10

|

38.3

|

152

|

80

|

42

|

180

|

165

|

12

|

45.3

|

||

|

MTC-110

|

6500

|

22

|

110

|

165

|

142

|

90

|

35

|

40

|

80

|

10

|

38.3

|

152

|

80

|

42

|

180

|

180

|

12

|

45.3

|

||

|

MTC-140

|

6500

|

29

|

140

|

210

|

142

|

90

|

40

|

40

|

110

|

12

|

43.3

|

152

|

80

|

48

|

180

|

210

|

14

|

51.8

|

||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

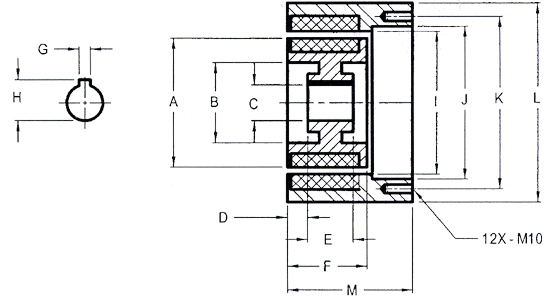

Technical Data

|

|

|

Inner Cylinder

|

300 Stainless Steel, Hermetically Sealed

|

|

Outer Cylinder

|

Mild Steel, All Magnets Encapsulated

|

|

Magnet (Nickel-Plated)

|

NdFeB*

|

|

Operating Temp*

|

140C (284F)

|

|

*Note: Co-Axial couplings are also available with SmCo magnets, rated up to 280C (536F)

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Note: The MTC-0.1 through -10 containment shells are 316 stainless, and are rated to a minimum of 30 Bar. Containment shells for other sizes are made to order and are rated according to customer requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||