Electromagnetic Brakes | Electromagnetic Clutches

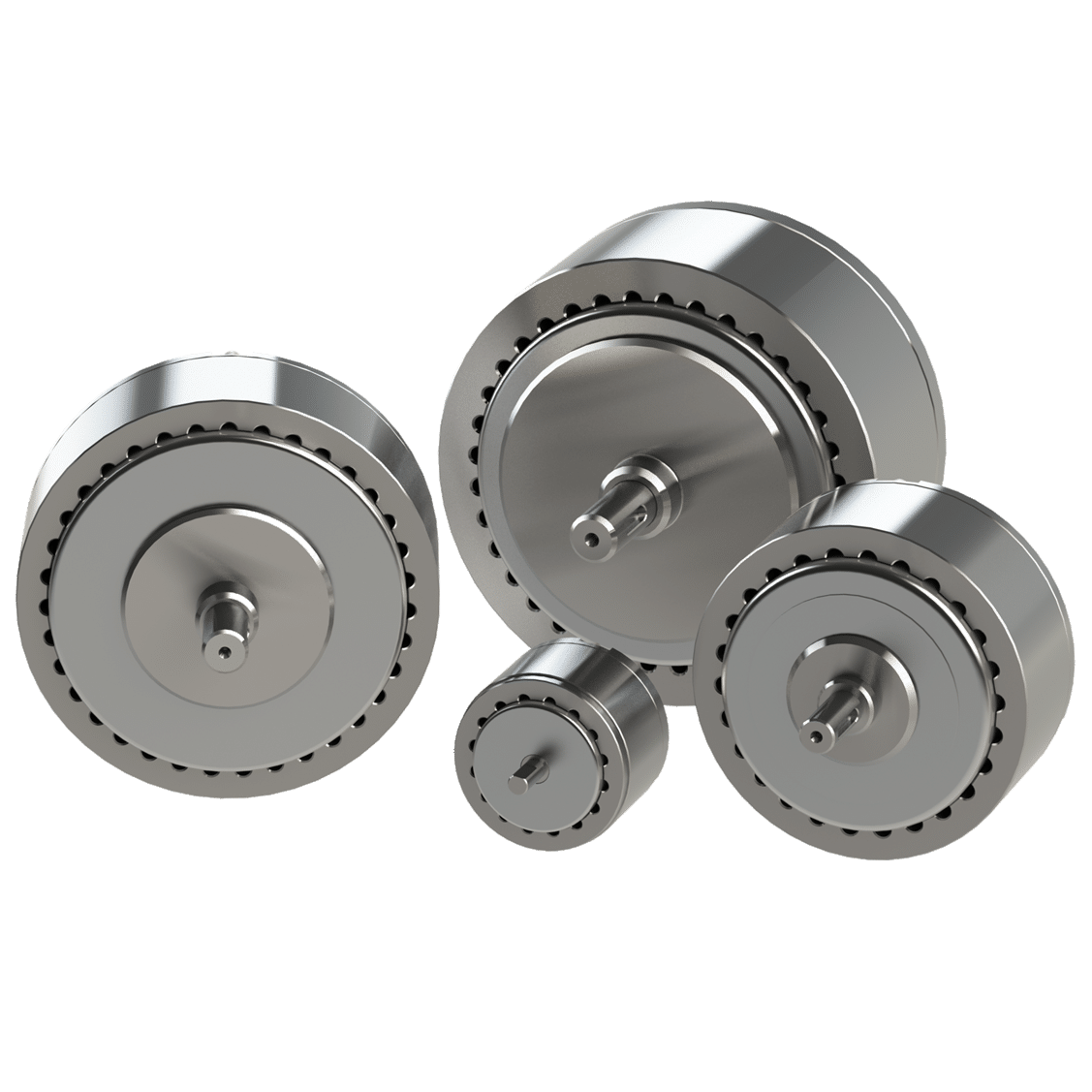

Electromagnetic brakes and electromagnetic clutches

- These electromagnetic brakes and electromagnetic clutches utilize an electromagnet to generate drag torque

- Drag torque is dependent on input current and independent of slip speed, a constant current power supply such as our MPP24 must be used

- Torque on each unit can be adjusted to any value between bearing drag (~0) and the max torque indicated in the table below by adjusting input current

- Select an electromagnetic brake or electromagnetic clutch based on torque requirement

- Refer to heat curve on product data sheet to ensure speed and torque of your application will not exceed heat rating of brake

- Refer to product data sheet for dimensional data

Model

Max Torque [IN-LB]

Product Datasheet

Solidworks 3D Model

Step 3D Model

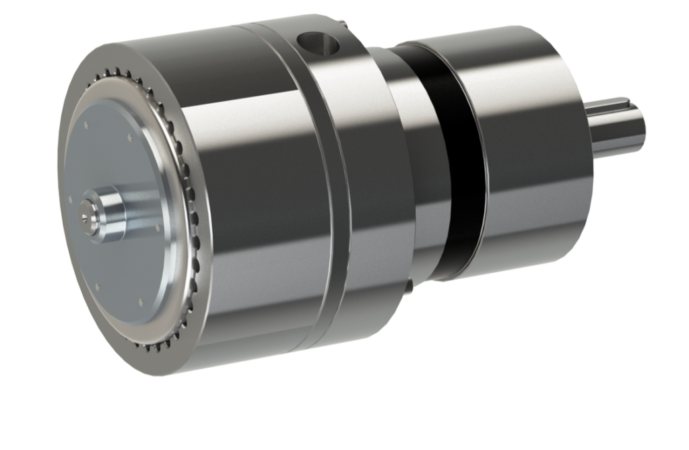

Gearbox Brakes

These brakes utilize an electric hysteresis brake paired with an integral gearbox. Ideal for applications that require high torque at a low speed. Available in a variety of gear ratios depending on torque requirements up to 450 ft-lb.

Model

Max Torque [FT-LB]

Product Datasheet

Solidworks 3D Model

Step 3D Model

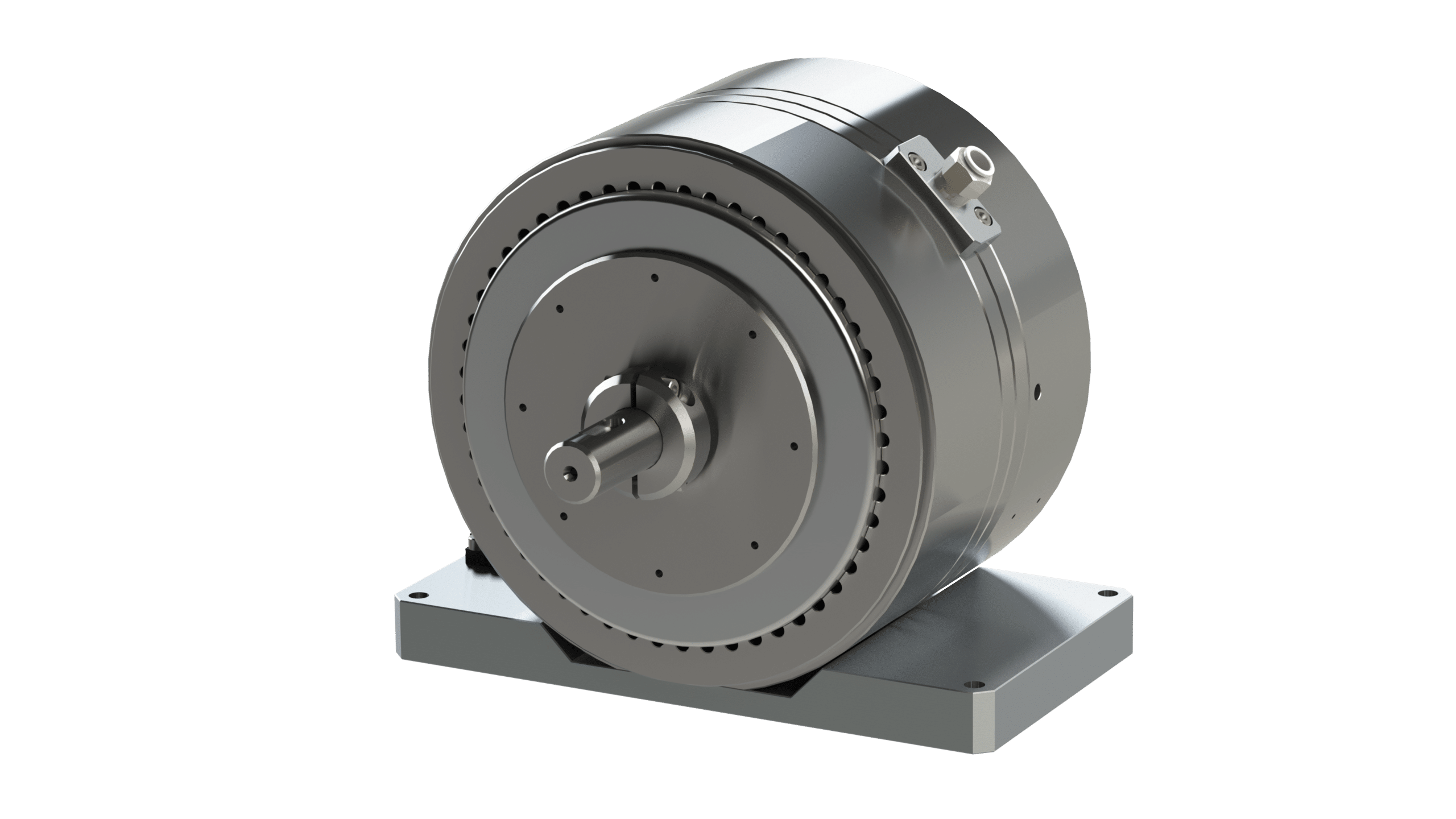

Air-Cooled Brakes

These brakes offer air-cooling using compressed air. Ideal for high-speed applications which are dissipating considerable heat.

Model

Max Torque [IN-LB]

Product Datasheet

Solidworks 3D Model

Step 3D Model

Electromagnetic brakes and elecgtromagnetic clutches for Motor Testing

Electric Hysteresis brakes are often used for motor testing. When used in conjunction with our MPP24 power supply, they allow for a programmable duty cycle to be used to subject a motor to a realistic loading conditions. For high-power motors, we offer air cooled versions of our brakes to allow for more power to be dissipated by the brake.

Constant Tension Payoff

For specialized or sensitive processes that require precise and constant tension control, our electromagnetic brakes and electromagnetic clutches can be used in conjunction with our MPP24 Tension Controller in order to achieve either open-loop or closed-loop constant tension control. This is especially useful for applications that undergo a large diameter change (large ratio between full spool diameter and empty spool diameter).